Our Equipment

View our equipment below.

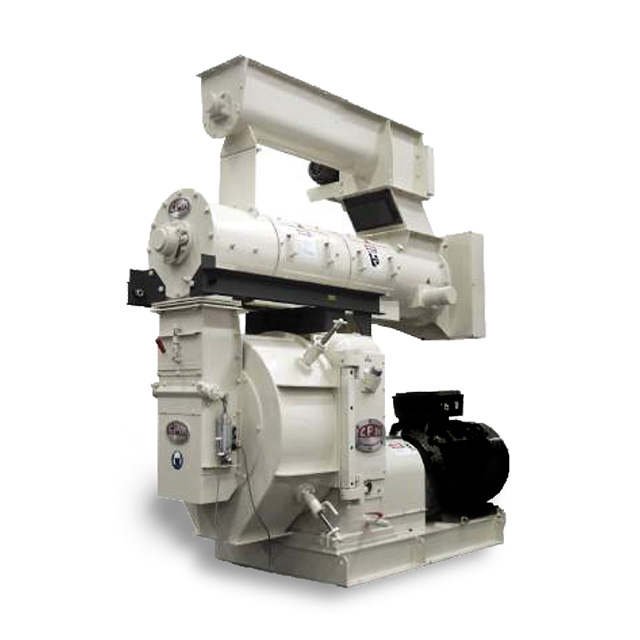

Pellet Mill Set

CPM 3022-2,5

Description

- Heavy duty cast gear case for quieter operation

- Pellet chamber & shear pin safety

- Direct driven motor with 132kw installed

- Trapped key interlock

Conditioner

Feeder

Technical Details

Die Diameter: 572 mm

Die width: 60 mm

Die surface: 1078 (cm2)

Die speed: 210/270 (rpm)

Pmax: 110 (kW)

Pricing

Minimum financing term:

Minimum lease term:

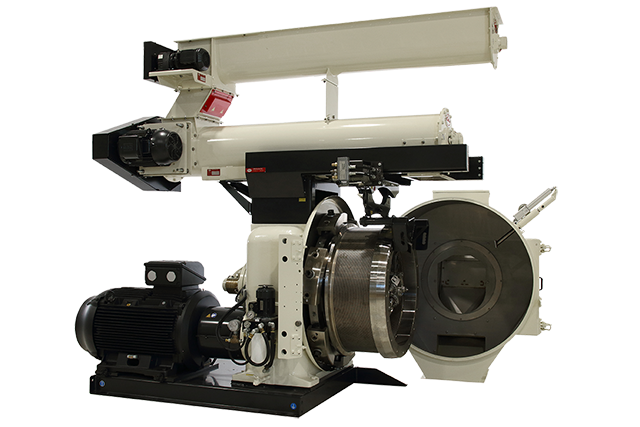

Pellet Mill Standalone

CPM 3022-2,5

Description

The 3022-2,5 stand-alone pellet mill, is built with the highest possible standards in the industry this gear-driven masterwork of engineering will uplift your pelletising line to a higher level. The oil-lubricated roller will ensure improved process control and longer lasting rollers.

Technical Details

Die width: 60mm

Die surface: 1078 (cm2)

Die speed: 210/270 (rpm)

Pmax: 110 kW (kW)

Pricing

Minimum financing term:

Minimum lease term:

Pellet Mill Set

CPM 7730-4

Description

Conditioner

Feeder

Technical Details

Die width: 94 mm

Die surface: 2250 (cm2)

Die speed: 150/210 (rpm)

Pmax: 200 (kW)

Pricing

Minimum financing term:

Minimum lease term:

Pellet Mill Standalone

CPM 7730-4

Description

Technical Details

Die width: 94 mm

Die surface: 2250 (cm2)

Die speed: 150/210 (rpm)

Pmax: 200 (kW)

Pricing

Minimum financing term:

Minimum lease term:

Benefits of choosing NXT Technologies

Curabitur vel metus congue, porttitor sem id, tincidunt felis

Vestibulum tempus mi at velit congue, sed auctor dolor laoreet.

Morbi et quam euismod, fringilla purus ac, vulputate eros.

Pellentesque euismod est eu nisi finibus, vitae congue nisi cursus.

Vivamus congue lorem non facilisis lacinia.

Phasellus sit amet ipsum a quam cursus congue non non magna.

Sed non metus sit amet justo pulvinar auctor.

Any questions about our stock?

Do you want to know more about our products?

Please let us know!